Epoxidised Natural Rubber (ENR) is derived from the partial epoxidation of the natural rubber molecules, resulting in a totally new type of elastomer. It is a modified natural rubber having the properties resembling those of synthetic rubbers rather than natural rubber. Epoxyprene25&50 indicating Epoxyprene25&50 epoxidation level. Epoxidation results in a systematic increase in the polarity and glass transition temperature; these increase are reflected in the vulcanized properties.

Property changes with increasing level of epoxidation include: An increase in damping, a reduction in swelling in hydrocarbon oils, a decrease in gas permeability, an increase in absorption of microwave energy, an increase in silica reinforcement, improved compatibility with polar polymers like polyvinyl chloride, reduced rolling resistance and increased wet grip. The epoxidation process also reduces the level of protein inherent of the starting natural rubber.

Epoxyprene25&50 is a sustainable “Green” material can be used in anti-vibration mountings, surrounds for audio speakers, machinery, road vehicles and railway coaches, high damping/shock absorption/anti-slip for footwear component, acoustic devices, bladders & inner tubes, etc. A compatible blend with PVC can be used to further increase the damping of Epoxyprene25&50, with the additional advantage of enhancing ozone resistance.

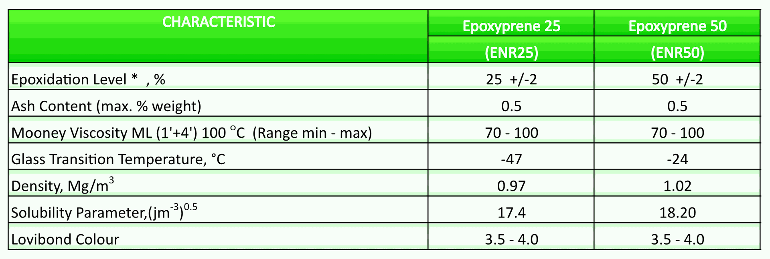

SPECIFICATIONS

* Nuclear Magnetic Resonance (NMR) Spectrometer Test Method.

PACKAGING

Dimensions Per Pallet : 1,424 mm (L) x 1,124 mm (W) x 1,120 mm (H)

Net Weight Per Pallet : 1,200 Kgs

No. Of Bales Per Pallet : 36

Net Weight Per Bale : 33.33 +- 0.5 Kgs

Bale Wrapper : Thin (0.035mm) or Thick Polybag (0.09mm)